This year we welcomed Cecelia Lamancusa (below left) and Chesca Basillo (below right) as our summer interns. Their six week stay with us was all too brief, and Friday, August 6th, they ended their summer program and said goodbye. In addition to shadowing clinicians and learning about fabrication, they each had a project to focus on with a Dankmeyer mentor.

Cecelia moves on in a few weeks to her first semester at the Prosthetics and Orthotics master’s program at the University of Pittsburgh. She had this to say about her summer with Dankmeyer:

"During my internship, I shadowed prosthetists and orthotists as they interacted with various patients, either in need of prosthetic limbs or braces. I observed and provided assistance as they evaluated, casted molds, and fitted prostheses and orthoses for each client. When I wasn’t shadowing, I was writing, recording, and editing for a video project that was meant to encompass what is a prosthesis. Through this project, I interviewed patients that wanted to share their experience. They were all filled with passion and pride as they talked about their prosthetic limbs. They were also not afraid to discuss the hardships that come with wearing a prosthesis. I gained a better understanding of the complexity of a prosthesis and how it’s so much more than a device. While my previous internships always allowed me to see the perspective of the practitioners, this one allowed me to also see and understand the perspective of the amputee."

While Cecelia spent time behind the camera, Chesca was focused on working in the lab on various 3D printing research projects, which she will be able to use when she applies to prosthetics and orthotics programs this fall.

“During the six weeks at Dankmeyer, my project was centered around the 3D printers. I have assisted with calibrating different filaments and adjusting settings to ensure the best quality in a print. After calibration, custom parts for AFOs and prostheses were drawn up in a CAD software, sliced, and printed to be used for fabrication. For example, a test socket was printed out of PCTG (a plastic resin). This filament is clear when printed properly and can be heat molded, making it a functional material to print a test socket. Along with 3D printing, I got to use my experience in a research lab and applied my knowledge by helping with a current prosthetic foot study that Dankmeyer was participating in for Ottobock.”

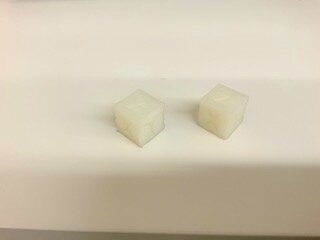

Chesca produced and organized binders full of information. She helped collect data and did some data entry and fact checking for this study. You can see the results of some of her 3D printer work below. The picture on the left shows bridging calibration shapes. Some are better than others, but that’s the point; to fine tune the printer to the specific material. On the right, you see a close-up of a calibration cube out of nylon. The cube on the left is an early print (notice the rough edges, blobs, and poor definition), the right is after the printer settings were tuned for the material.

We are sorry to see them go, but very happy to have contributed to their knowledge of O&P. We look forward to seeing their great contributions to the O&P profession.