I hold a special place in my heart for the University of Maryland, College Park. I’m a Terp-for-life, and graduated from Maryland with a bachelors degree in bioengineering in 2004 (my father and sister are also Maryland alum). You can find my name on the grounds at College Park engraved at the ODK fountain on the mall, as well as on a brick outside of the Alumni Center.

So when I was approached last fall by Dr. Kiger, the Director of Undergraduate Studies at the Department of Mechanical Engineering at UMD, about teaching a brand new class on 3D printing and prosthetics to undergrads, I was beyond thrilled.

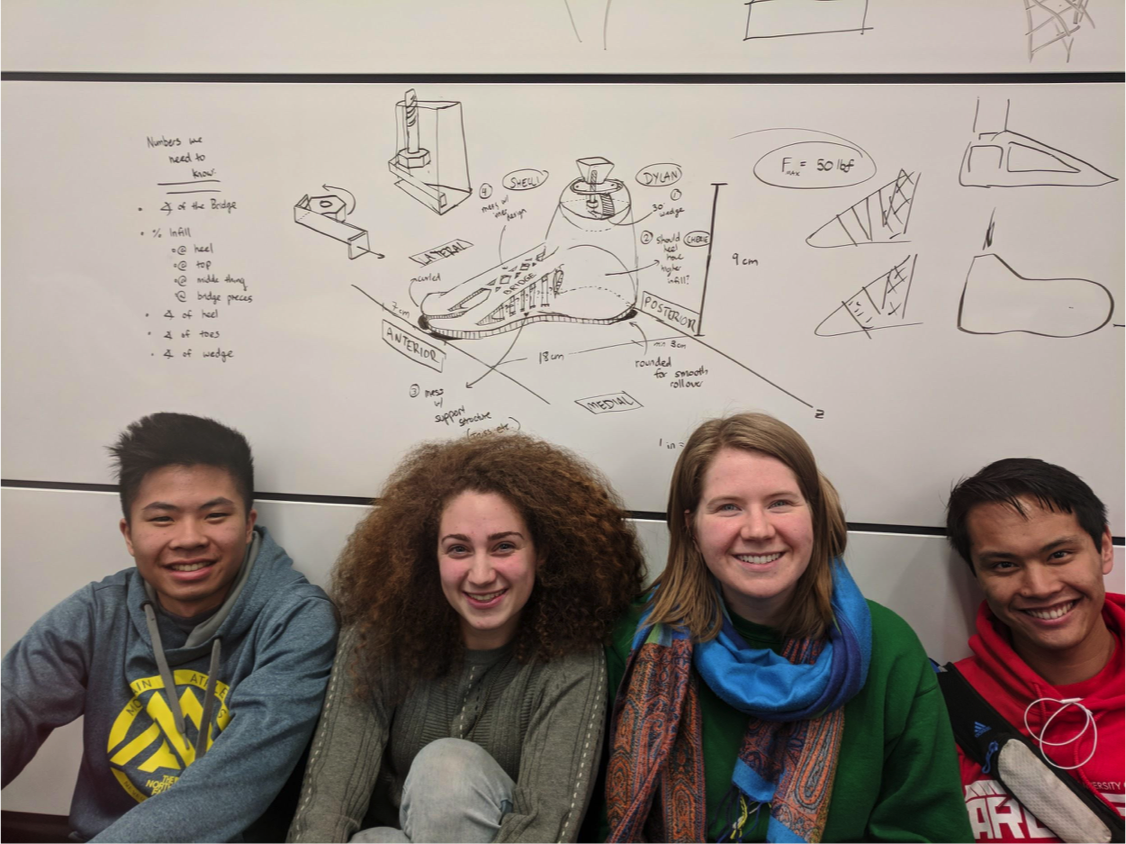

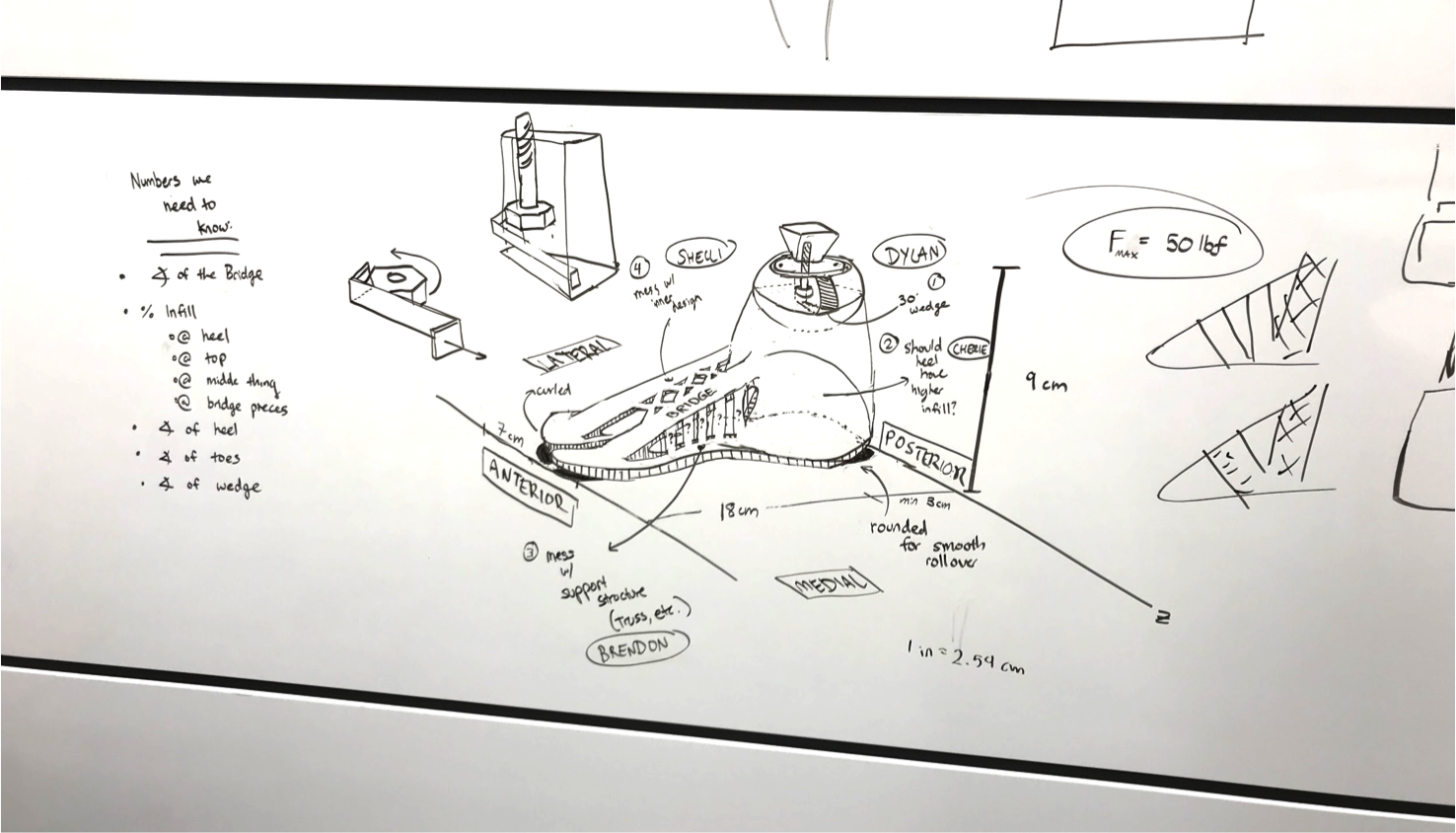

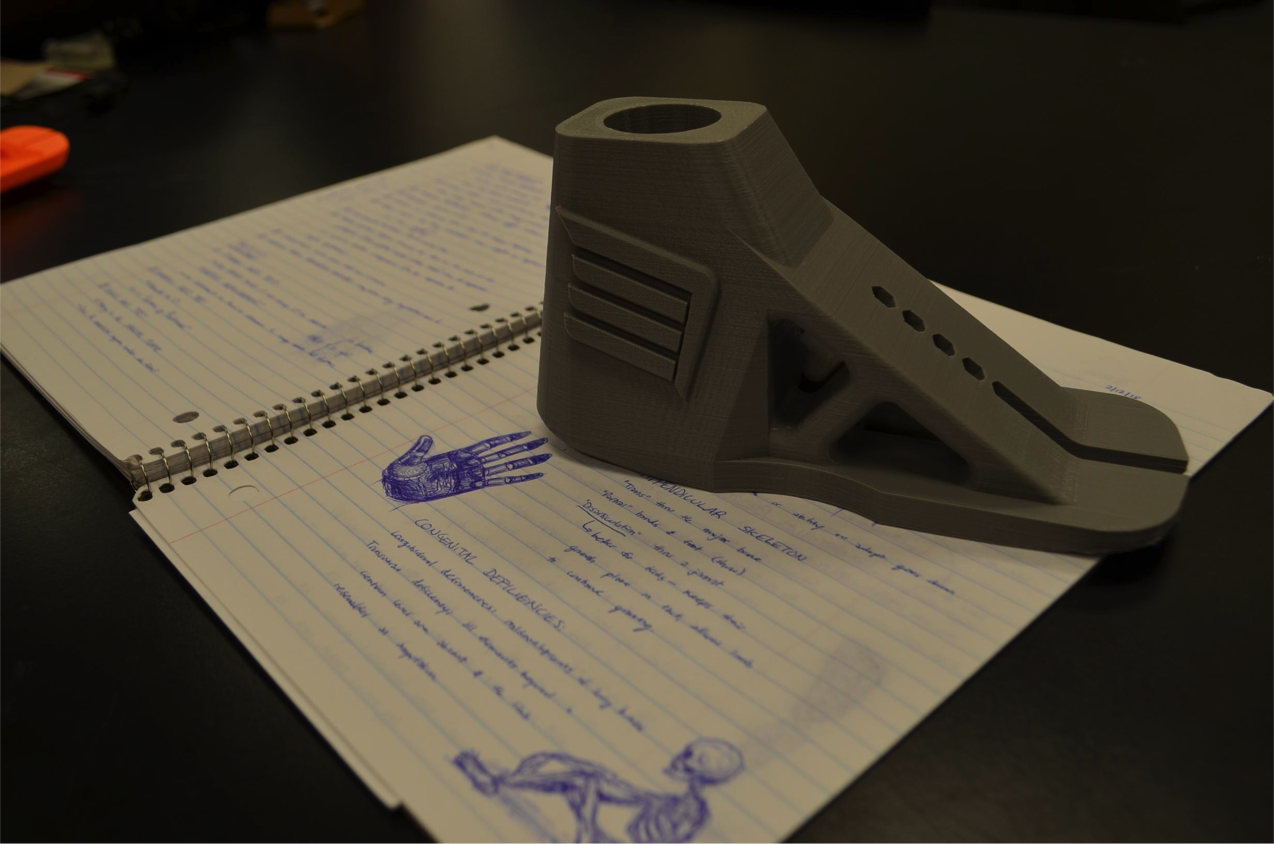

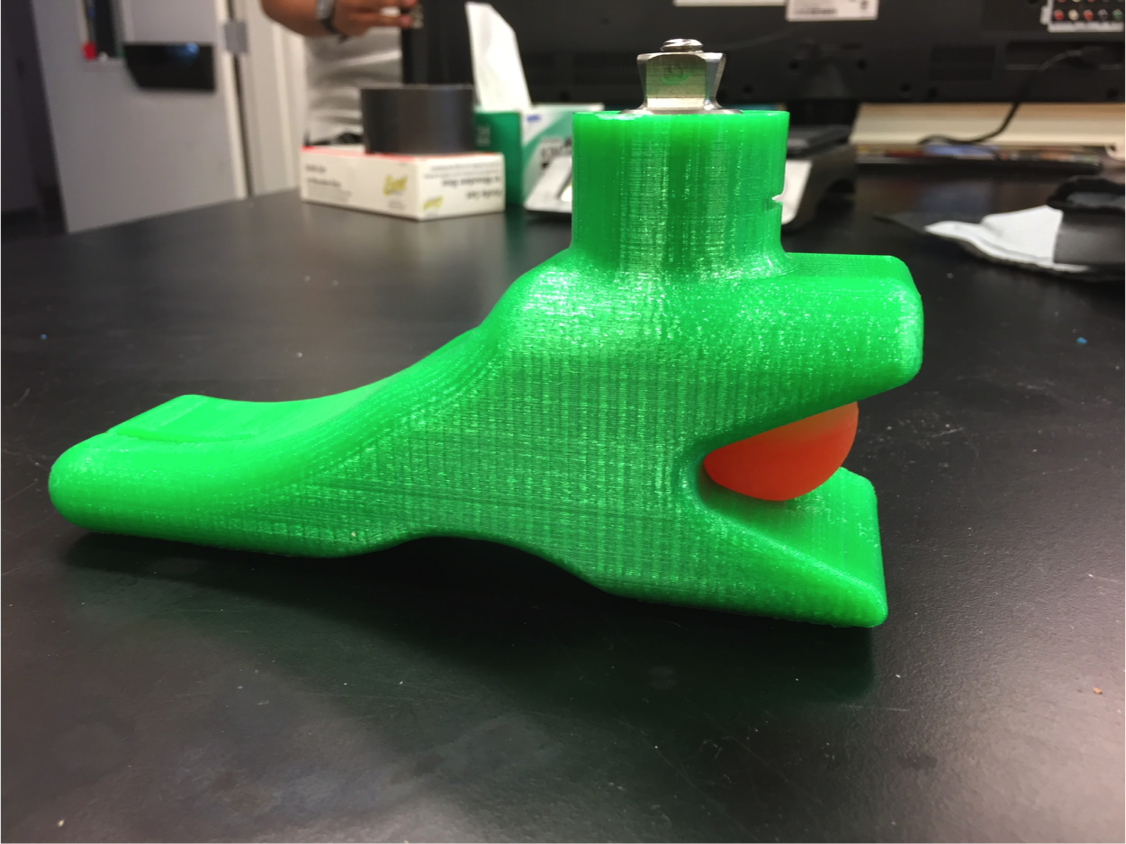

I got paired up with two insanely smart mechanical engineering Juniors, Saul and Anna, who know much more than I do about additive manufacturing (3D printing). Together we designed the course from scratch. We made it into a project based course, where the students’ main objective would be to creatively design a 3D printed prosthetic foot for a child and test its ability to withstand impact loading. We would provide them with the background knowledge on prosthetic design and additive manufacturing throughout the semester, and they would work in teams to create, CAD, print, test, and refine their designs.

This class was held during the Spring 2018 semester. Since I work normal hours at Dankmeyer during the day, we had to keep the class to evenings only. Who wants to take a 3 hour class on Monday nights for 15 weeks?!? But people did. Not only did we fill our allotted class size of 20, but extended it to 3 more waitlisted students who were eager to get in.

And these students were bright. They brought to the class their energy, eagerness to learn, creativity, and amazing computer aided design skills. While most were engineering students, we had one majoring in art and another in political science, and a few were international students from study abroad programs, bringing together a variety of diverse talents and backgrounds.

As part of their final deliverable, each team produced a short video on their project, including their design process, testing, and lessons learned. I was blown away with their work and want to share a couple of my favorite videos of theirs with you:

For a first-time class, it was a huge success overall. There are certainly areas that we want to improve on for next time, and we are excited to announce that there WILL be a next time! We are working on the revised content and are slated to return with version 2 of “Additive Manufacturing and Prosthetic Design” in Spring 2019.