One hundred students in grades 4-12 representing four Anne Arundel schools, and their community partners gathered together to complete their project on 3D printing of prosthetic hands.

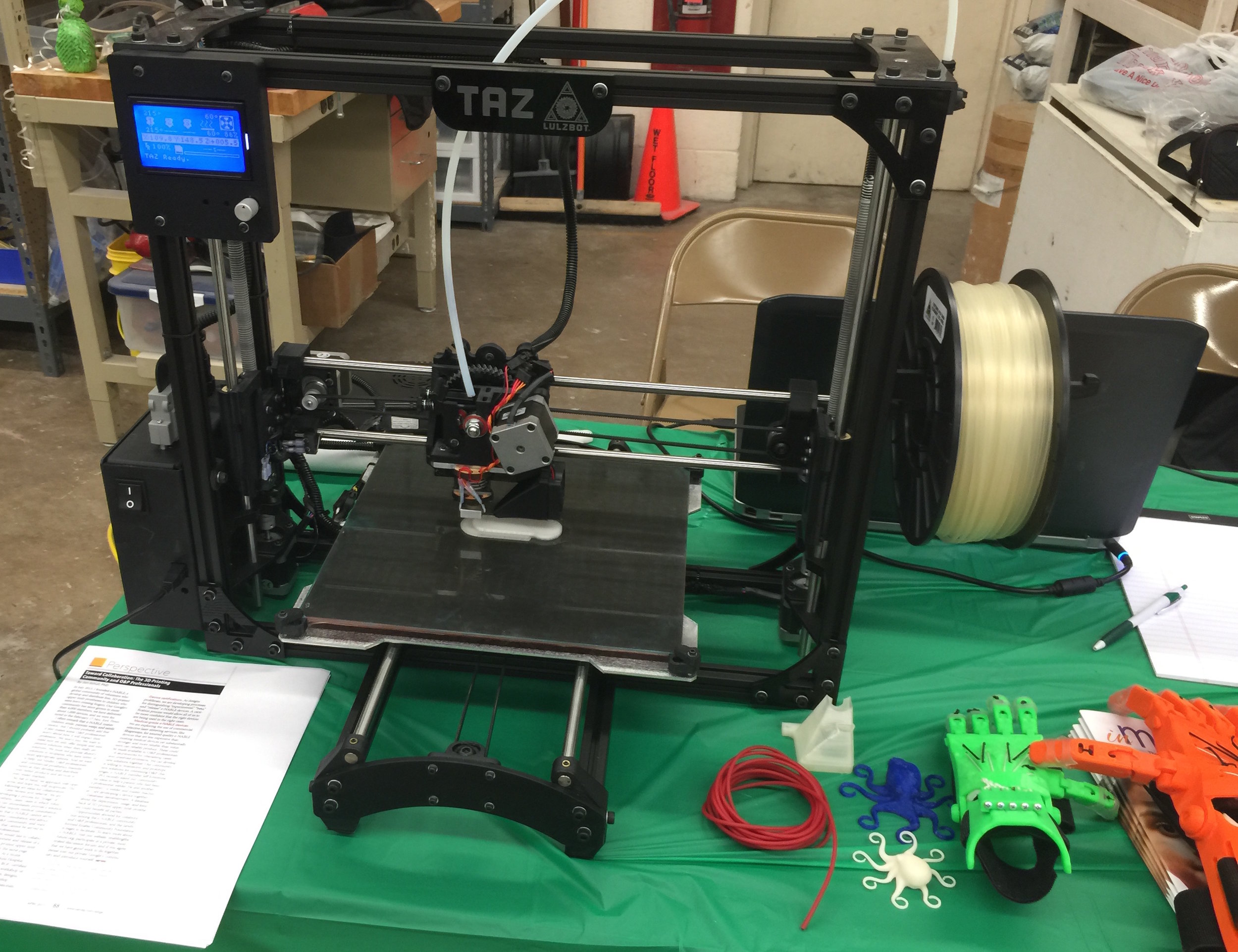

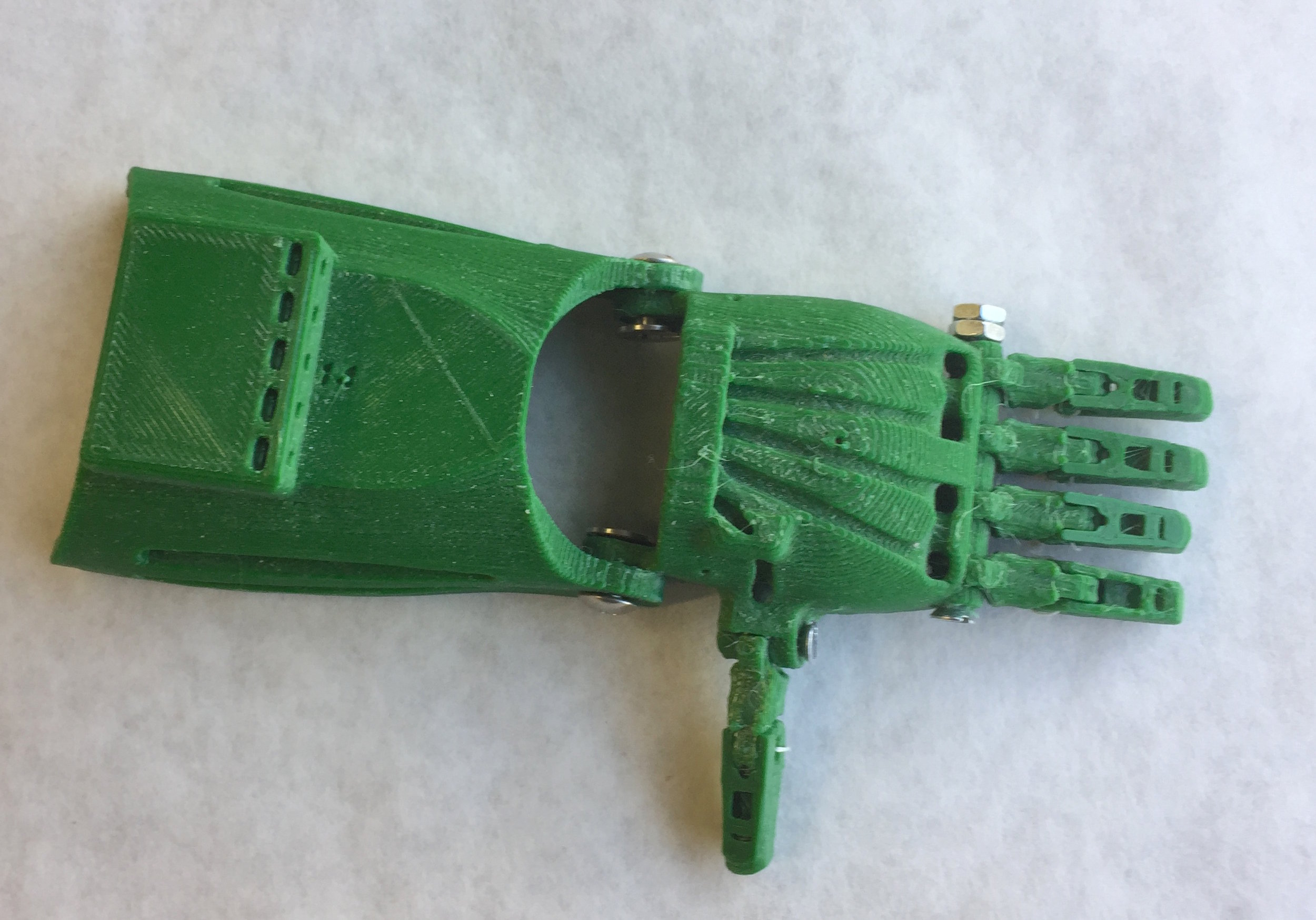

This Problem Based Learning project, focused on prostheses, wrapped up Saturday April 23, 2016 when students from the Anne Arundel schools gathered at North County High School in Glen Burnie, MD. The E-Nable Helping Hands Event allowed the Science, Technology, Engineering, and Mathematics (STEM) students to connect after their months long work on the project. The Helping Hands event was designed to provide one hundred STEM students with an opportunity to work with new 3D printing technology, encourage “out of the box” thinking, and interact with community partners. During the school year, these students from grades 4-12 have focused on upper limb prostheses, particularly prosthetic hands. Class activities have included design and drawing of prosthetic hands for multiple active functions, writing a children’s book about prosthetic devices, and the 3D printing of prosthetic hands.

Dankmeyer, Inc provided support at various levels, starting with hosting visiting students in the Linthicum office earlier in the spring. There students attended a presentation given by Kristen Beltran, Resident Prosthetist Orthotist, and toured the facility, with the opportunity to see a lamination and plastic drape molding in the lab. Kristen also went to schools with demonstrations of upper and lower limb devices. Saturday’s event included rotations to different areas showcasing the works of the various participant schools. One rotation included professionals at work - so Art Ross, Prosthetic & Orthotic Lab Technician, and Kristen joined the students at the event with a Dankmeyer display and presentation on prosthetic and orthotic clinical practice. They provided additional information on prostheses and orthoses, with demos of terminal devices that serve a variety of recreational and daily use purposes, such as golf, kayaking, basketball, eating, cooking, and using tools. The students were excited and curious to see how prosthetic devices operate.

- Contributed by Kristen Beltran and Art Ross